SAE J20 EPDM Reinforcement Automotive Radiator Coolant Hose rau Txias System

| Khoom siv: | SAE J20 EPDM Reinforcement Automotive Radiator Coolant Hose rau Txias System |

| Yam khoom No.: | JBD-D011 |

| Loj & Zoo: | ID≥Φ2 hli; Customized raws li xav tau. |

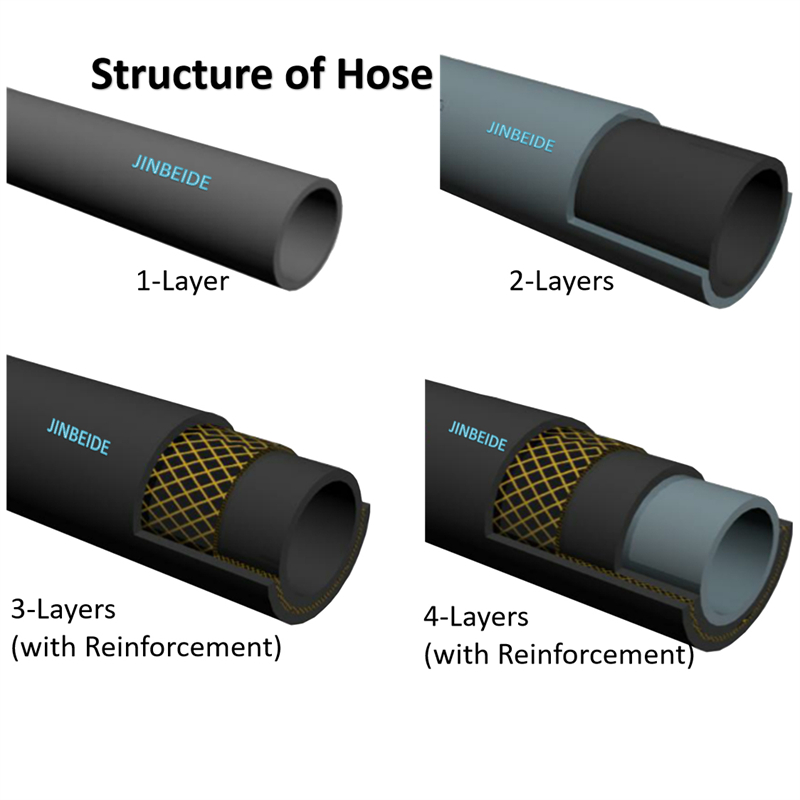

| Khoom siv: | EPDM; EPDM / EPDM; EPDM / YARN / EPDM |

| Qauv: | 1-3 Txheej |

| Xim: | Dub |

| Txuj | SAE, YDK, HES, EX-S, ASTM thiab lwm yam |

| Daim ntawv thov | siv hauv Cov Cuab Yeej Cuab Yeej hauv Tsheb, Tsheb, Tsheb kauj vab, ATV, Cav, Cov Khoom Siv Hluav Taws Xob Sab Nraud, Cov Tshuab Hluav Taws Xob, thiab lwm yam. |

| Chaw nres nkoj Shipping | Xiamen |

| OEM/ODM | Txais |

| Pob | PE hnab + Carton + Pallet |

| Cov nqe lus them nqi | T / T, L / C, Western Union |

| Hoobkas | ISO / IATF16949 sau npe |

| Cov kws tshaj lij | 30+ Xyoo kev paub |

| Qauv Leadtime | 7-15 hnub |

| Production Leadtime | 20-30 hnub |

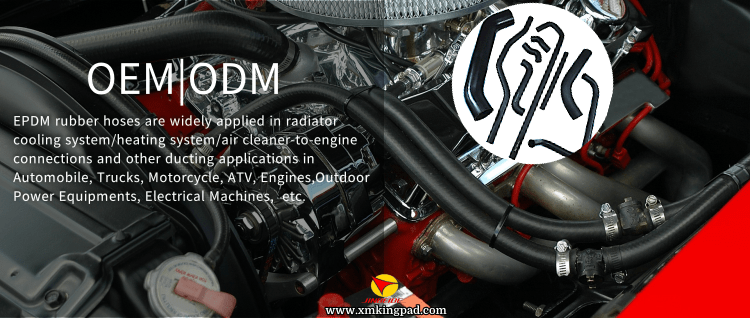

OEM & ODM

SAE J20 EPDM Reinforcement Automotive Radiator Coolant Hose tuaj yeem txais OEM & OEM raws li tus neeg siv khoom kos duab, qauv thiab lwm yam tshwj xeeb, ua tau raws li qhov yuav tsum tau ua raws li tus qauv ntawm SAE, YDK, HES, EX-S, ASTM,

SPECIFICATION

| Test Report | ||||||

| ■ Kev Xeem Khoom Siv Khoom | Test Standard: | SAE J20 R4 D1 | ||||

| ■ Cov Khoom Muag Khoom Muag | ||||||

| Khoom siv: | EPDM COOLANT HOSE | |||||

| Cov khoom kuaj (JBD) (SAE J20 R4 D1) | JBD Kev kuaj mob (SAE J20 R4 D1) | Test Cov ntsiab lus | Chav tsev | JBD Tus nqi pib | ||

| ORIGINAL STATE | Chav ntsuas kub 20 ℃ ~ 30 ℃ | HARDNESS | HS | 65 ± 10 | ||

| TENSILE HEEV | MPA | ≥7 | ||||

| ELONGATION | % | ≥250 | ||||

| HEAT AGED TEST | 72H × 125 ℃ | HARDNESS HLOOV | HS | ± 15 | ||

| TENSILE HEEV HEEV | % | Max: -20 | ||||

| TXOJ CAI TSHIAB ELONGATION | % | Max: -50 | ||||

| COMPRESSION SET | 72H × 125 ℃ | COMPRESSION TSET HLOOV | % | ≦70 | ||

| COOLANT IMMERSION | Boiling Point * 72h (112 ℃ - 115 ℃) * 72 H | HARDNESS HLOOV | HS | ± 10 | ||

| TENSILE HEEV HEEV | % | Max: -20 | ||||

| TXOJ CAI TSHIAB ELONGATION | % | Max: -50 | ||||

| VOLUME HLOOV | % | -5 ~ + 20 | ||||

| Adhesion ntawm txheej | / | Adhesion ntawm txheej | KN/M | > 1.5 | ||

| Txias FLEXIBILITY | -40 ℃ × 5h, Flexed 180 degree × 10 zaug | / | TSIS MUAJ CRACKS | |||

| Circumferential swell ntawm overpressure | Max 10% circumferential o ntawm lub hose tso cai thaum nias ntawm 2xOP @ 110 ℃ sab hauv kub, thaum 5 feeb. (OP: 180kPa thiab -10kPa hauv Kos duab) | / | Tsis muaj qhov tawg tawg lossis lwm yam tsis xws luag | |||

| Lub tshuab nqus tsev vacuum | Lub tshuab nqus tsev rau 15s ~ 30s @ 0.083 MPa; , Lub pob nrog ib txoj kab uas hla ntawm 0.8 npaug ntawm txoj kab uas hla ntawm lub hose tuaj yeem hla tag nrho cov hose | / | Tsis muaj qhov tawg tawg lossis lwm yam tsis xws luag | |||

| Kev kuaj pom | cm3/s. | |||||

| Kev ntsuas tawg | Tus nqi ntawm kev siv lub siab yuav tsum tsis pub tsawg tshaj 2.0 MPa, los yog ntau tshaj 7.0 MPa / min. | MPa | ≥1.24 MPa (siab tshaj) | |||

| OZONE RESISTANCE | 40 ℃ × 50 mpa × 72 H | / | TSIS MUAJ CRACKS | |||

| KINK TEST | % | <20% | ||||

APPLICATION

SAE J20 EPDM Reinforcement Automotive Radiator Coolant Hose dav siv hauv Radiator Txias System / cua sov system / cua nqus tsev vacuum-rau-cav sib txuas thiab lwm yam dej siv hauv tsheb, tsheb thauj khoom, tsheb thauj mus los txhua qhov chaw (ATVs), Motorcycles, Snowmobiles, Cav, Sab Nraud Fais Fab Cov khoom siv, thiab Generators.

Peb Uniquie Advantages:

A: 30+ Xyoo Kev Ua Haujlwm Kev Ua Haujlwm Pabcuam nrog R & D Center muaj zog.

B: Muaj peev xwm muaj peev xwm nrog 4 Factories Production Base.

C: Kev ruaj ntseg zoo thiab tus nqi sib tw —-Peb yog lub tuam txhab kev sib koom ua ke ntawm Rubber Raw Materials Refining & Tov Khoom Txheej Txheem thiab tsim cov khoom siv roj hmab nrog cov kws tshaj lij, nrog rau Roj Hmab Raw Materials Wholesales.

D: Lub sij hawm xa tuaj - 20-30 hnub rau kev tsim khoom loj.

Qauv ntawm Hose

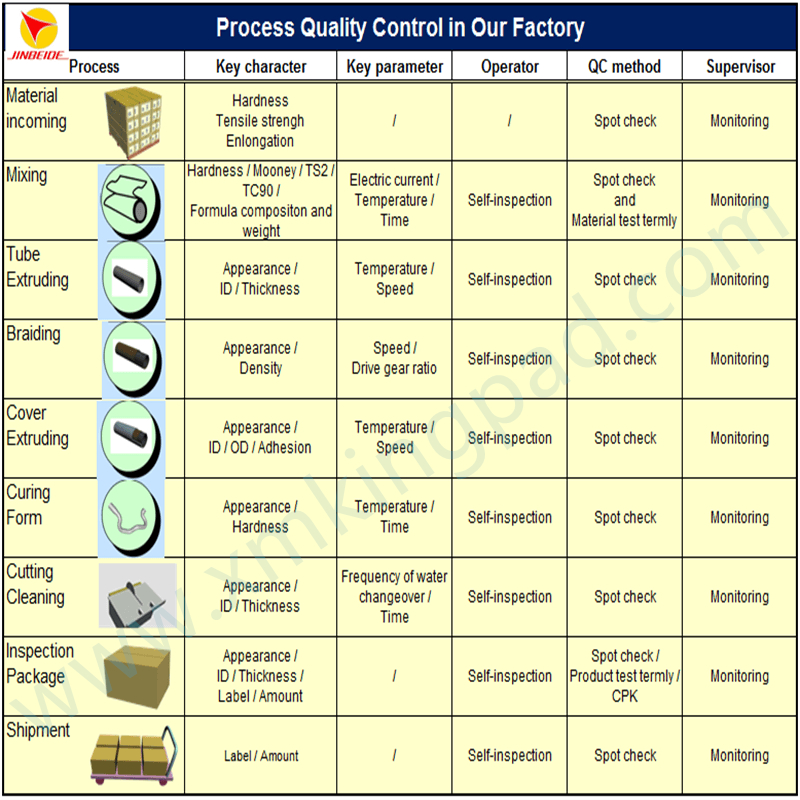

Txheej Txheem Kev Tswj Xyuas Zoo

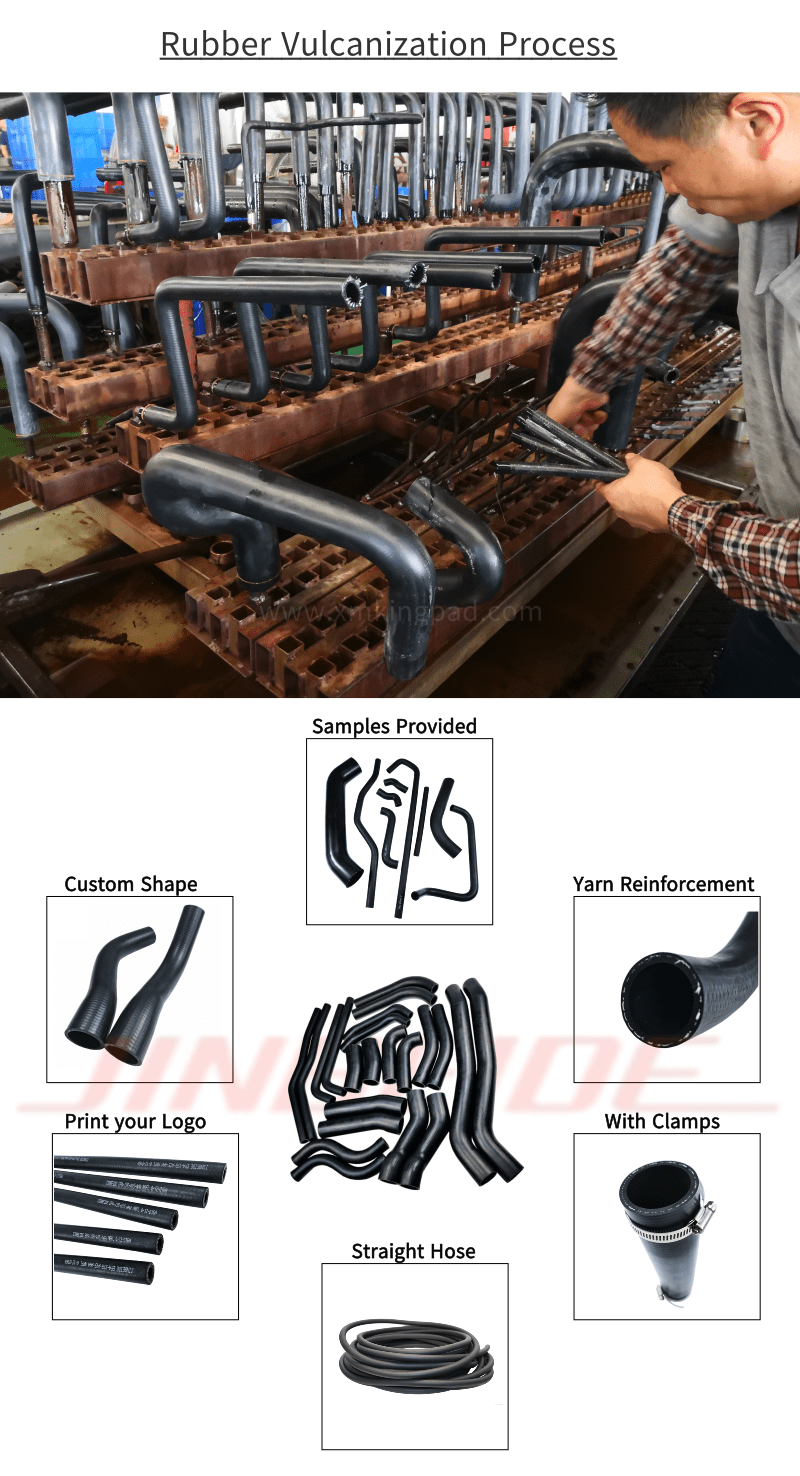

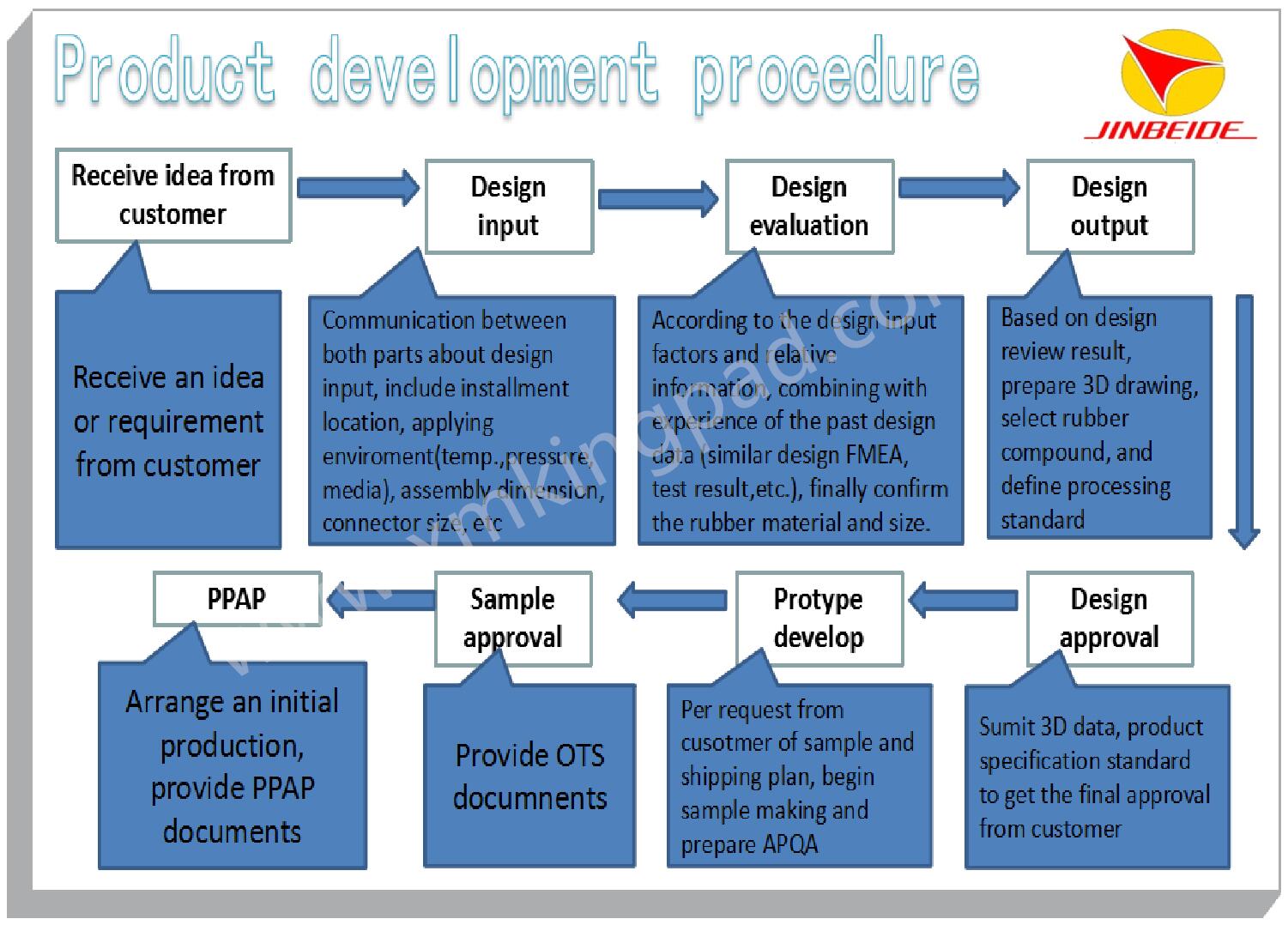

Txheej txheem ntawm kev tsim khoom

Khoom Sau

Ntim & Shipping

| Test Report | ||||||

| ■ Kev Xeem Khoom Siv Khoom | Test Standard: | SAE J20 R4 D1 | ||||

| ■ Cov Khoom Muag Khoom Muag | ||||||

| Khoom siv: | EPDM COOLANT HOSE | |||||

| Cov khoom kuaj (JBD) (SAE J20 R4 D1) | JBD Kev kuaj mob (SAE J20 R4 D1) | Test Cov ntsiab lus | Chav tsev | JBD Tus nqi pib | ||

| ORIGINAL STATE | Chav kub 20℃~ 30℃ | HARDNESS | HS | 65 ± 10 | ||

| TENSILE HEEV | MPA | ≥7 | ||||

| ELONGATION | % | ≥250 | ||||

| HEAT AGED TEST | 72 H × 125 hli℃ | HARDNESS HLOOV | HS | ± 15 | ||

| TENSILE HEEV HEEV | % | Max: -20 | ||||

| TXOJ CAI TSHIAB ELONGATION | % | Max: -50 | ||||

| COMPRESSION SET | 72 H × 125 hli℃ | COMPRESSION TSET HLOOV | % | ≦70 | ||

| COOLANT IMMERSION | Boiling Point * 72 teev (112℃-115℃)*72 H | HARDNESS HLOOV | HS | ± 10 | ||

| TENSILE HEEV HEEV | % | Max: -20 | ||||

| TXOJ CAI TSHIAB ELONGATION | % | Max: -50 | ||||

| VOLUME HLOOV | % | -5 ~ + 20 | ||||

| Adhesion ntawm txheej | / | Adhesion ntawm txheej | KN/M | > 1.5 | ||

| Txias FLEXIBILITY | -40℃× 5 h,Flexed 180 degree × 10 zaug | / | TSIS MUAJ CRACKS | |||

| Circumferential swell ntawm overpressure | Max 10% circumferential o ntawm lub hose tso cai thaum nias ntawm 2xOP @ 110℃ sab hauv kub, thaum lub sij hawm 5 feeb. (OP: 180kPa thiab -10kPa hauv Kos duab) | / | Tsis muaj qhov tawg tawg lossis lwm yam tsis xws luag | |||

| Lub tshuab nqus tsev vacuum | Lub tshuab nqus tsev rau 15s ~ 30s @ 0.083 MPa; , Lub pob nrog ib txoj kab uas hla ntawm 0.8 npaug ntawm txoj kab uas hla ntawm lub hose tuaj yeem hla tag nrho cov hose | / | Tsis muaj qhov tawg tawg lossis lwm yam tsis xws luag | |||

| Kev kuaj pom | cm3/s. | |||||

| Kev ntsuas tawg | Tus nqi ntawm kev siv lub siab yuav tsum tsis pub tsawg tshaj 2.0 MPa, los yog ntau tshaj 7.0 MPa / min. | MPa | ≥1.24 MPa (siab tshaj) | |||

| OZONE RESISTANCE | 40℃× 50mpa × 72H | / | TSIS MUAJ CRACKS | |||

| KINK TEST | % | <20% | ||||